This review looks at a DIY biquad antenna kit from WarDrivingWorld.com, for making an 802.11b/g wireless networking antenna. The contents of the kit are reviewed, and comments are provided on the construction of the antenna. The completed antenna is then tested and compared with several other biquad antennas.

Background

Several years ago, I published detailed instructions on building a biquad antenna on my website.

The biquad is relatively easy to build yourself, and offers very good performance for its size and complexity. A biquad typically has a gain of 11dBi, with approximately 40 degree beamwidth. It can be used as a standalone antenna, or it can be used as a feed on a larger dish.

While many people have used my instructions to build their own biquad antennas, some people do not necessarily have the tools required to construct these antennas, or do not know where to source the components required.

WarDrivingWorld sent me a kit to review, as they had previously asked if they could distribute a printout of my Biquad Antenna Construction page with their kits. The kit arrived in a USPS cardboard envelope with a US-based source address.

mail package

Kit Contents

The WarDrivingWorld kit comes complete with all the parts required to build a biquad antenna, and is neatly packaged in a sealed plastic bag.

bag containing the kit

Contents of the bag are:

- pre-drilled copper PCB (123x123mm)

- female panel-mount N-connector with solder lug

- approx 350mm 2.5^mm copper wire

- short length of silver solder

Similarly, I did not receive any instructions, but apparently a printout of my Biquad Antenna Construction page is normally included with the kit (and is used with my permission).

contents of the kit

The length of silver solder provided with the kit is lead-free. Apparently silver solder is more conductive than tin/lead solder, due to its silver content, and produces joints which can be upto 5-10 times stronger than joints made with tin/lead solder.

Silver solder also has a lower melting point than tin/lead solder, thus allowing it to be used with less heat than similar tin/lead solder.

The copper PCB measures 123x123mm, and has a hole pre-drilled in the centre for the N-connector. The hole is not cleanly drilled - it has rough edges, and is not circular, and probably is a little larger than is necessary. However, the edges of the hole can be easily cleaned up with a round file in a minute or two.

Construction

The copper surface of the PCB was cleaned up with some steel wool. It is important to clean the copper surface around the hole in the centre of the PCB, to ensure a good electrical connection when the N-connector is screwed into place.

Also, aesthetically, a polished copper surface looks much nicer than an oxidised surface. However, the copper surface will oxidise again, and will not retain its polished appearance (unless it is sealed), but the oxidisation should have no impact on the performance of the antenna.

As already mentioned, the burrs on the edges of the hole in the centre of the PCB were removed with a small round file.

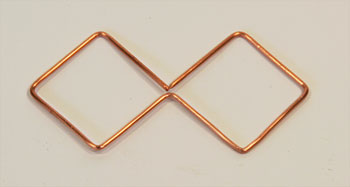

The copper wire was straightened, and then bent into the shape required for the biquad element, with each side being as close to 30.5mm as possible. (Refer to the Biquad Antenna Construction page for more details.)

biquad element

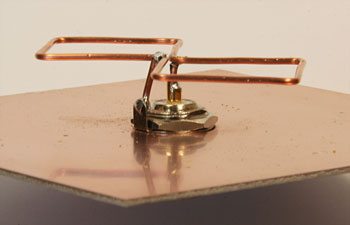

The N-connector was inserted into the hole in the PCB, with the solder end on the copper side of the PCB, and the N-connector end on the blank side of the PCB.

Note that I placed the washer with the solder lug on the copper side of the PCB too, and bent the solder lug up at a 90 degree angle, to allow it to be used as an attachment point for the element feed.

To build the biquad element feed, a short length of copper wire was soldered into the centre post of the N-connector, and another was attached to the solder lug. Once attached, these two wires were measured and trimmed at approx 14.5mm away from the PCB copper surface (to ensure the biquad element would be 15mm away from the PCB).

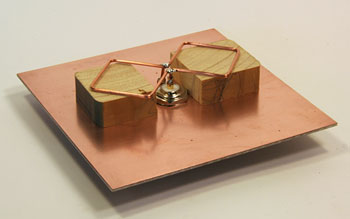

I cut two pieces of wood 14.5mm thick, and used these to support the biquad element while soldering it to the feed on the N-connector.

soldering the biquad element

The Biquad Antenna Construction page mentions the need for a shielded feed to the biquad element (ie, the section between the biquad element and the PCB reflector).

However, the WarDrivingWorld kit only provides components for building a biquad with an unshielded feed. An unshielded feed will radiate, and this will have a detrimental impact on the antenna's performance.

(Refer to the test results below for more details on performance.)

side view of element mounting detail

showing the solder lug attachment on the right

element mounting detail

The resulting biquad antenna is somewhat fragile, as the biquad element can easily be bent or knocked out of shape.

completed biquad antenna

This can be rectified by using a plastic spacer between the edges of the biquad element and the PCB reflector, to securely hold the biquad element in place, and to make the antenna much more robust.

I use plastic spacers, made out of a small section of reticulation riser, with a small cable tie through it.

detail of plastic spacer

Note that the spacers can be made from almost any non-metallic (microwave-transparent) material. If desired, hot-melt glue can be used to attach the spacers, but be aware that the hot-melt glue will get very soft if you mount your biquad in direct sunlight.

Testing

To test the effectiveness of the WarDrivingWorld biquad, I compared its performance with one of my martybugs biquad antennas, and with a martybugs double biquad antenna.

Note that the martybugs biquad has a shielded feed, and has a slightly smaller PCB reflector (110x110mm, while the WarDrivingWorld biquad has a 123x123mm biquad). The smaller reflector is due to the fact that the martybugs biquad was originally built to be used as a feed on a dish.

Test results for a client connection to SGNet:

| antenna | SNR (dB) |

signal (dBm) |

noise (dBm) |

SNR diff (dBm) |

| martybugs biquad | 47 | -54 | -101 | |

| WarDrivingWorld biquad | 46 | -55 | -101 | -1 |

| martybugs double biquad | 51 | -51 | -102 | +4 |

A similar test was performed by establishing a client connection to the 360 degree slotted waveguide on ArmadaleAP, another WAFreeNet access point, approx 300m away (which has an Orinoco RG1000 access point).

Test results for a client connection to ArmadaleAP:

| antenna | SNR (dB) |

signal (dBm) |

noise (dBm) |

SNR diff (dBm) |

| martybugs biquad | 26 | -73 | -99 | |

| WarDrivingWorld biquad | 25 | -76 | -101 | -1 |

| martybugs double biquad | 28 | -74 | -102 | +2 |

The test results indicate that the gain of the WarDrivingWorld biquad is about 1dBi less than that of the martybugs biquad. This is due to the unshielded feed on the WarDrivingWorld biquad, while the martybugs biquad has a shielded feed.

Note that the dB scale is logarithmic (where 3dBi is a doubling of signal strength), and 1dBi is approximately equivalent to 25% of the signal.

Note that the martybugs biquad had a slightly smaller reflector (110x110mm instead of 123x123mm), so the difference in performance between the two biquads may be slightly more than 1dBi if a 123x123mm reflector were to be used on the martybugs biquad.

The gain of the double biquad has previously been measured as 2-3dBi higher than that of the martybugs biquad (3dBi is a doubling of signal strength), and these test results confirm this.

Summary

This kit provides all the components required to allow you to build a biquad antenna with minimal tools, and without having to source components from multiple sources.

While the biquad has a bare radiating feed, this has a relatively small impact on the performance of the antenna (reducing the gain by about 1dBi down to approx 10dBi). The bare feed is also simplifies antenna construction significantly.

This DIY biquad kit from WarDrivingWorld is also very good value. At the time of writing, the kits were being sold on eBay for US$22.95 + US$5.50 postage and handling, resulting in a total cost of approximately AUD$37.

I priced each of the components individually (all prices are in $AUD):

| component | cost |

| blank PCB (150x150mm) | $6.20 |

| female panel-mount N-connector | $5.00 |

| 1 metre of 2.5mm^2 T&E power cable | $3.60 |

| pigtail | $25.00 |

| total | $39.90 |

Note that 1 metre of 2.5mm^2 twin&earth power cable (the minimum length most stores will sell) will provide enough copper wire for at 6 biquad elements, but the above prices assume a user wants to construct a single biquad antenna.

If the cost of 1 metre of cable is distributed across 6 biquad antennas, the total cost per antenna drops to AUD$36.90.

This confirms that the WarDrivingWorld biquad kit is certainly very good value for money. It provides all the items required to build a biquad, and doesn't even require any cutting or drilling, as the PCB is pre-cut to the correct size, and is pre-drilled.

The only tools required for constructing the WarDrivingWorld biquad are a pair of pliers (for bending and cutting the biquad element), and a soldering iron or gas torch to solder the element.

In summary, it's a useful kit that is very good value for money, particularly for users who want to build a biquad with minimal effort.

The robustness of the antenna can easily be improved by the user with some plastic spacers, and if required, the gain can be slightly increased by making a shielded feed (but this will require additional components that are not included in the kit).