Biquad Antenna Construction

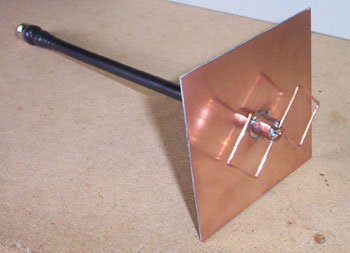

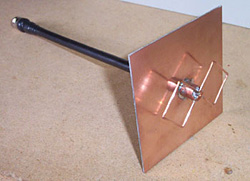

This page details the

construction of a biquad antenna. The biquad antenna is easy

to build, and provides a reliable 11dBi gain, with a fairly

wide beamwidth.

Background

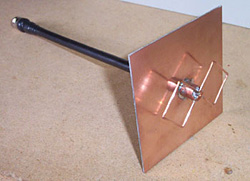

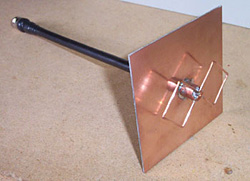

completed biquad

antennaI've done quite a bit of

experimentation and testing with various home

made dipoles for 24dBi Conifer dishes, and have managed to

increase the performance of the dish.

completed biquad

antennaI've done quite a bit of

experimentation and testing with various home

made dipoles for 24dBi Conifer dishes, and have managed to

increase the performance of the dish.

Parts Required

I used the

following bits and pieces:

- 123x123mm square section of blank PCB

- 50mm length of 1/2" copper pipe

- short length of CNT-400 or LMR-400 low loss coax (~300mm

long)

- 250mm of 2.5mm2 copper wire (approx 1.5mm

diameter)

- N connector

Note that you don't have to use

blank PCB for the reflector. You can use any material that's

electrically conductive, can be electrically connected to the

coax braid, and will reflect microwaves (ie, any metal plate

will do fine).

I've also heard of people using CDROM as

the reflector, as the foil on it will certainly reflect

microwaves.

Reflector

Cut a square piece of

blank printed circuit board, 123x123mm.

Note that Trevor

Marshall recommends a size of 123x123mm if using the

biquad as a stand-alone antenna, while 110x110 is optimal if

using it as a feed for a large dish.

He also recommends

attaching some lips to two sides of the reflector, to reduce

radiation from the rear lobes.

Use some steel wool to

remove any tarnish and polish it up. Cleaning the copper in

this way will make it easier to solder.

blank printed circuit

board

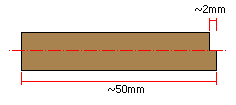

Cut a 50mm section of copper pipe,

and file both ends smooth. Using some sandpaper and/or some

files, polish up the copper pipe (including the inside of the

copper pipe, to ensure a good connection with the coax braid).

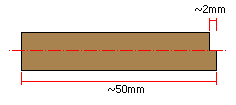

the dimensions of

the copper pipe

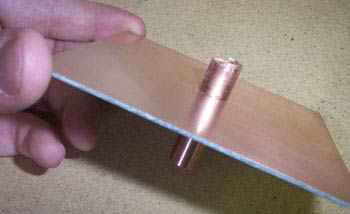

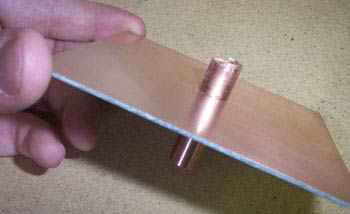

Cut a notch into one end

of the copper pipe, removing approx 2mm from half the

circumference.

a short secion of copper

pipe, notched at one end

Drill a hole in

the centre of the blank PCB so that the copper pipe is a tight

fit in the hole. I found a reamer to be very useful for

enlarging the hole to the correct size.

making a hole in the

centre

Insert the copper pipe into the

hole, with the notched end on the copper side of the blank

PCB. The copper pipe should be protruding approx 16mm through

the hole, measured on the copper side of the PCB.

insert the copper pipe into

the reflector

Solder the copper pipe to

the PCB, to ensure a good physical and electrical connection.

solder the copper pipe to

the PCB

Quite a bit of heat is needed, due

to the thickness of the copper pipe, and an electrical

soldering iron probably won't be able to deliver sufficent

heat. I found a small gas torch works quite well.

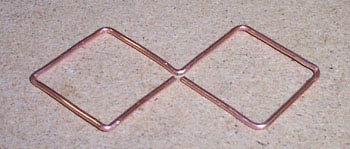

Making the Element

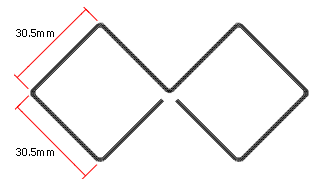

The element

is made from a length of copper wire, bent into the

appropriate shape.

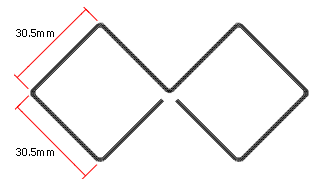

Note that the length of each "side"

should be as close to 30.5mm as possible (measured from the

centre of the copper wire to the centre of the copper wire),

which is a quarter of a wavelength at 2.4GHz

the shape and

dimensions of the element

I had some

offcuts of electrical power cable lying around, and found that

2.5mm2 power cable had a diameter of approx 1.6mm -

a little bigger than the 1.2mm that Trevor Marshall specifies,

but didn't think it would make a significant difference to the

performance of the biquad.

recycling power

cable offcuts

Remove the insulation,

measure and cut a 244mm length the copper wire, and straighten

it as best as you can.

straighten the wire

Measure the mid-point of the wire, and make a 90

degree bend. The bend should be quite sharp and pronounced.

90 degree bend

Measure the midpoints of each half, and make two

more 90 degree bends in the wire, so that it looks like that

shown in the photo below.

another two bends

Once again, measure the midpoints of each

section, and make some more 90 degree bends, resulting in what

is shown below.

bend it some more...

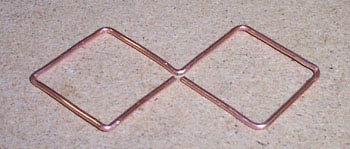

Do the same to the other side, resulting in the

biquad shape.

make it

symetrical...

Clean up all your bends, and

ensure each side of the element is as straight as possible,

and as close to 30.5mm as possible.

Note that you may need

to trim a small amount off each end of the wire to achieve

this.

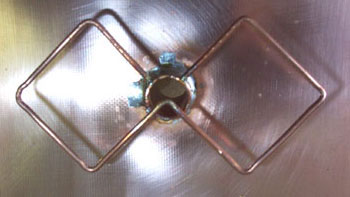

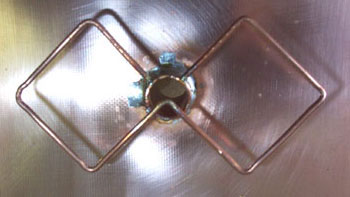

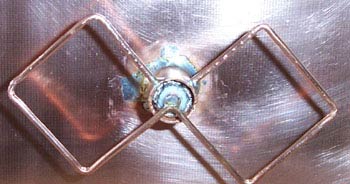

Assembly

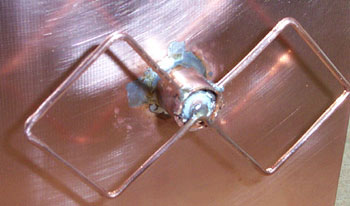

The element must now

be attached to the reflector. Note that only the two "ends" of

the copper wire are to be attached to the copper pipe - the

centre of the copper wire must not touch the copper pipe

(hence the notch which was cut into the end of the copper

pipe.

The copper wire element should be approximately

15mm away from the reflector. Testing antenna performance

while varying the spacing between the copper wire element and

the rear reflector indicates that a spacing of approx 15mm

provides the lowest SWR .

the element soldered onto

the copper pipe

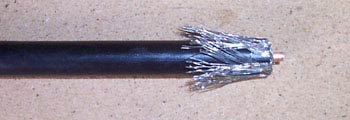

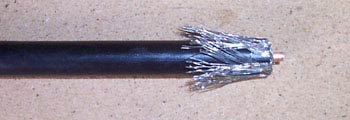

Strip approx 30mm of the

outer sheath from the end of the coax.

strip the outer

sheath

Fold the braid back over the outer

sheath, and trim the centre conductor, so that about 4mm is

protruding.

fold the braid back, trim

the centre conductor

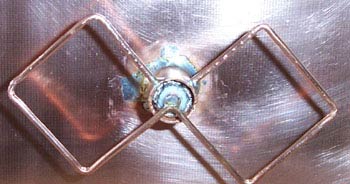

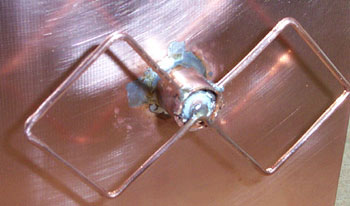

Insert the braid into

the copper pipe, so that the end of the centre conductor lines

up with the extreme end of the copper pipe, and solder the

centre of the element to it, ensuring the centre of the

element is not in contact with the copper pipe. Refer to some

of the additional photos below for details.

solder the centre

conductor to the element

another

view

Note that the feed between the rear

reflector and the biquad element needs to be shielded. Using

coax to feed the biquad element directly, and positioning the

coax inside the copper tube achieves this.

Use of bare

conductors as a feed between the reflector and biquad element

results in a radiating feed (such as this

one), which will have a detrimental effect on the biquad's

performance.

I used a coax crimper to crimp the end of

the copper pipe onto the coax. This ensures that the coax

would not move inside the copper pipe.

the copper pipe crimped

onto the coax

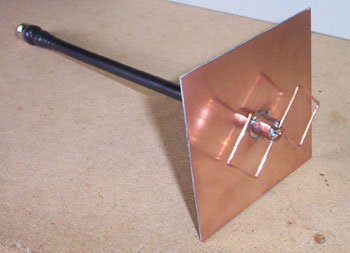

the completed

biquad

Now terminate the other end of the

coax with an N connector.

If desired, you can add

spacers at each end of the element, to ensure the element

doesn't move in relation to the reflector. Refer to my double

biquad page for more details on making spacers to support

the element.

If you intend to mount the biquad

outside, I'd recommend you place it into a weather-proof

enclosure, to prevent corrosion, and to prevent water ingress

into the coax.

Numerous people have used small tuppaware

containers successfully.

This can be achieved by

drilling a hole in one side of the container, and pass the

coax tail through the hole, leaving the biquad itself inside

the container. Seal up the hole for the coax with some

silicone, and your biquad should be protected against the

elements.

another view of

the completed biquad

Testing

Some very rough initial

testing using the biquad as a feed on a 24dBi Conifer dish

looks very promising, with the signal strength being at least

as as good as my home

made Conifer dipole (I was holding the biquad at

approximately the focal point of the dish, and hadn't even

removed the Conifer dipole).

I also managed to get a

marginal link to a 180 degree waveguide on an access point

10km away, using only the biquad by itself, connected to a

30mW RoamAbout wireless card.

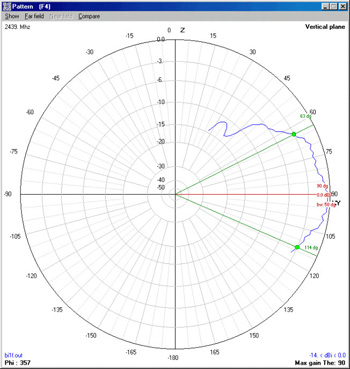

Some more detailed testing

with multiple antennas, including the biquad shown above,

indicates the biquad has a gain of approx 11-12dBi.

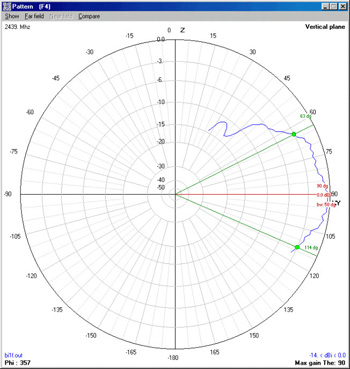

A

friend has access to some antenna test equipment, and

performed some tests on the biquad featured on this page.

The azimuth plot (ie, radiation pattern) of the biquad is

shown below, and shows a 3dB beamwidth of about 50 degrees.

azimuth plot of the

biquad

Usage

For information on

connecting a biquad antenna to a wireless radio, have a look

at the page on using

wireless antennas.

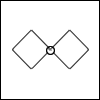

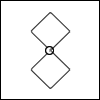

When using a biquad to

establish a link to another wireless device, you should ensure

the polarisation of the biquad is the same as the antenna you

are connecting to. Similarily, if establishing a link with two

biquads, ensure they are both oriented for the same

polarisation.

Failing to match the polarisation will

result in significant signal loss.

vertically

polarised |

|

horizontally

polarised

|

Changing the

polarisation is just a matter of rotating the entire biquad

antenna by 90 degrees.

The biquad antenna is not

particularly directional, but has a fairly wide beamwidth.

The 3dB beamwidth for a biquad (without side lips) is

typically about 40-50 degrees, thus making it ideal for any

applications where you want fairly wide coverage.

The

relatively wide beamwidth also makes a biquad very suitable

for war-driving and stumbling, allowing you to pick up signals

without having to align the antenna directly with the signal

source.

While a directional antenna, such as a Conifer

dish (3dB beamwidth of a 24dBi Conifer dish is approx 7

degrees), is better suited for point-to-point links, the

narrow beamwidth of a Conifer dish requires more precision

when aligning the antennas (the narrower the beamwidth, the

less susceptible it will be to interferance from other

sources). An antenna with a wider beamwidth, such as a biquad,

doesn't require the same precision for alignment, thus making

it easier to get a link working.

Variations

A number of people

have suggested the spacing between the element and the rear

reflector should be a 1/4 wavelength (ie, 30.5mm) instead of

15mm. However, test results

indicate the SWR of the biquad is minimised when the spacing

is about 15-17mm. Increasing the spacing to 30.5mm increases

the SWR significantly, thus reducing the efficiency of the

biquad.

Need More Gain?

For a

higher-gain variation of the biquad that's virtually just as

easy to build, have a look at the contruction details for a double

biquad antenna. The double biquad has approx 13 dBi gain.

Remember that the dBi scale is logarithmic, where 3

dBi is a doubling in gain. An increase in gain of 2 dBi is

equivalent to an increase of 60%.

Back to ... completed biquad

antenna

completed biquad

antenna completed biquad

antenna

completed biquad

antenna